REMOTE CONTROLLED, AUTOMATION

CAPABLE RC DRILLING SOLUTION

THE BBURG HD2500RC

For several years JSW has been developing its solution to the mining industry’s collective goal to improve safety: the BBURG HD2500RC.

IMPROVING SAFETY AND PERFORMANCE

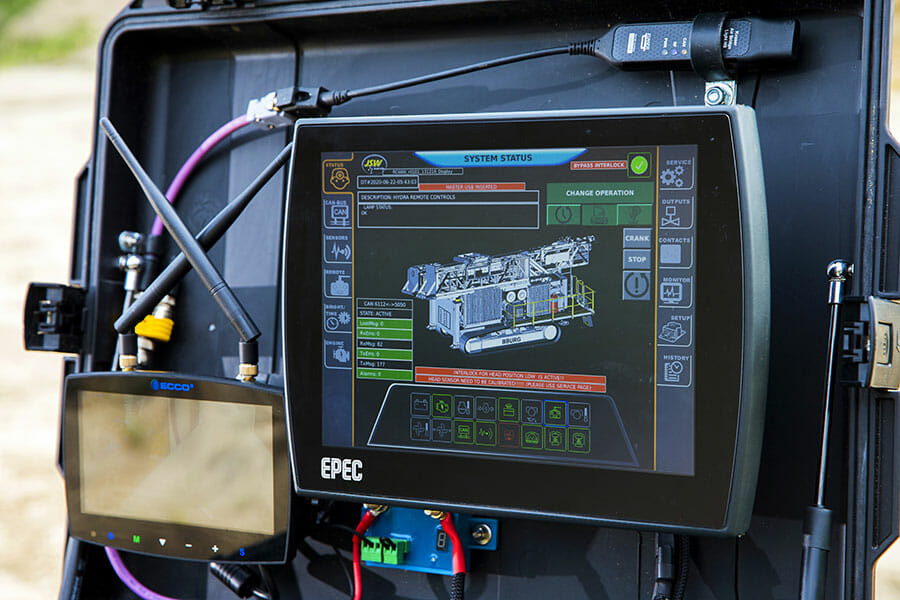

Our customised BBURG HD2500 reverse circulation (RC) drill rig features a remote control system that makes operating safer by removing people from hazards and dropped object zones.

The rig has been undertaking grade control at FMG’s Solomon iron ore mine in the Pilbara since July 2020 in conjunction with our project joint-venture partner and traditional owner group, the Eastern Guruma people.

To date, it has been producing exceptional outcomes in terms of safety, noise reduction and productivity.

ON THE PATHWAY TO AUTOMATION

Implemented with wireless remote control and developed specifically to handle the challenging Pilbara terrain, the rig’s design and automation capability is subject to ongoing advancements led by the team at our Bibra Lake workshop.

We continue to develop the drill’s capability, particularly in the areas of automated sampling and carbon neutrality as we seek to reach our own milestones and support our clients’ mandates in these areas, which will continue to be a key focus within the industry.

BBURG HD2500RC DRILL SPECIFICATIONS

The BBURG HD2500RC features:

- Low footprint with width of 3.5m

- High power with capacity to push 32.3cu.m/min of air at 500 psi down the hole

- Rod handler to increase productivity and improve safety

- 330m of rod capacity on board

- Full wireless remote control