The development of a unique drilling system by drilling contractor JSW Drilling is revolutionising the mineral sampling process when operating in challenging environments.

The Challenge

Exploration drilling operations face many challenges when working in environments with dense bushland, farmland, forestry, steep terrain, damp ground and/or within close proximity to communities.

Producing high quality samples in these conditions using conventional drilling methods can be challenging. The conventional vacuum drilling method struggles in wet ground while air-core drilling requires a larger footprint drill due to the higher energy requirements for air consumption.

Given the considerable environmental considerations, drilling operations need equipment with a small footprint and low environmental impact.

The Total Solution

As part of its commitment to providing specialised drilling solutions, JSW has designed and developed a drill bit and drilling method, along with a special purpose, small footprint drill carrier.

The unique ‘Vac-core’ method facilitates effective drilling in wet ground conditions and variable chip and sample sizes which can be adapted to client requirements – and it delivers quality results.

The carrier is an all-terrain customised tractor-mounted carrier which has 450mm of ground clearance allowing it to climb over fallen logs, large granite boulders and other forest debris, and can operate on 30+ degree slopes. It requires no clearing or access tracks and its low pressure footprint leaves minimal trace of its presence.

Additional Benefits

The rig has in-built safety measures to prevent injury and damage from working in forestry environments.

Both the driller and offsider are protected by an engineered and rated overhead protection system whilst drilling. The driving cab of the machine is both ROPS and FOPS. It’s fitted with a rod cage and all rod changing is hands free with a 20m capacity rod carousel.

The rig is licensed for the road allowing great flexibility and access between work areas.

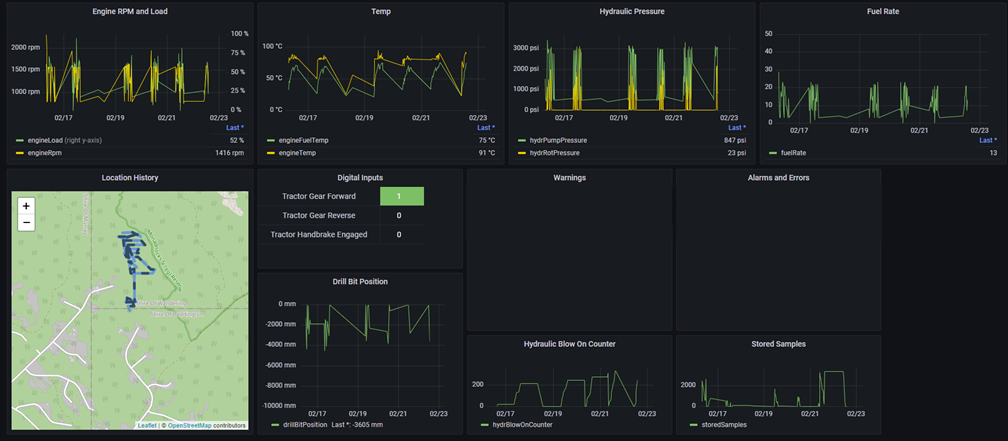

Full custom PLC and sensors electronic system fitted to each machine features inhouse data capture, and data transmission technology allows for recording and reporting of drilling activity in real time via web portals. The technology provides single point data entry, reduces processing times and facilitates greater visibility of project progress and productivity.

The Equus drilling system provides real-time drilling activity

The Outcome

Producing the best possible sample in varying difficult ground conditions, safely and with minimised environmental impact has been a game-changer for mineral explorers operating in challenging environments.

Want to know more?